How much does a 3D-printed house cost? We’ll cover how much it will cost to build your own 3D-printed house, how the construction process works, and the materials that are used. You might be surprised to learn that the cost of a 3D-printed house is less than you might think.

Cost of 3D-printed houses

While the cost of 3D-printed houses is still very high, a number of companies have made significant progress in the field. Companies such as SQ4D and Apis Cor have produced proof-of-concept houses with construction costs of less than ten thousand dollars. Other companies, such as WASP, have adopted innovative techniques to reduce costs. In some cases, they are using non-traditional materials like clay to create housing.

The cost of 3D-printed houses can vary from $1,000 to 500,000 USD. There are several factors that influence the cost of 3D-printed houses. However, if the cost can be made more affordable, it could be a game changer in the housing industry. As this technology is a relatively new concept, it comes with the costs associated with developing the technology.

The technology used in 3D-printed houses is referred to as contour-crafting. This process starts with a blueprint and a modeling software program. Then, a robotic arm moves around the blueprint using rails. The finished product can then be customized to meet the needs of the homeowner.

The cost of 3D-printed houses is significantly lower than conventional construction methods. The material used in the process is typically one order of magnitude less than the costs of conventional methods, with the exception of concrete, which is higher than normal. In addition, the labor costs are reduced to the wages of two or three operators, so that 3D-printed houses can be completed in a few days, rather than months.

Construction process

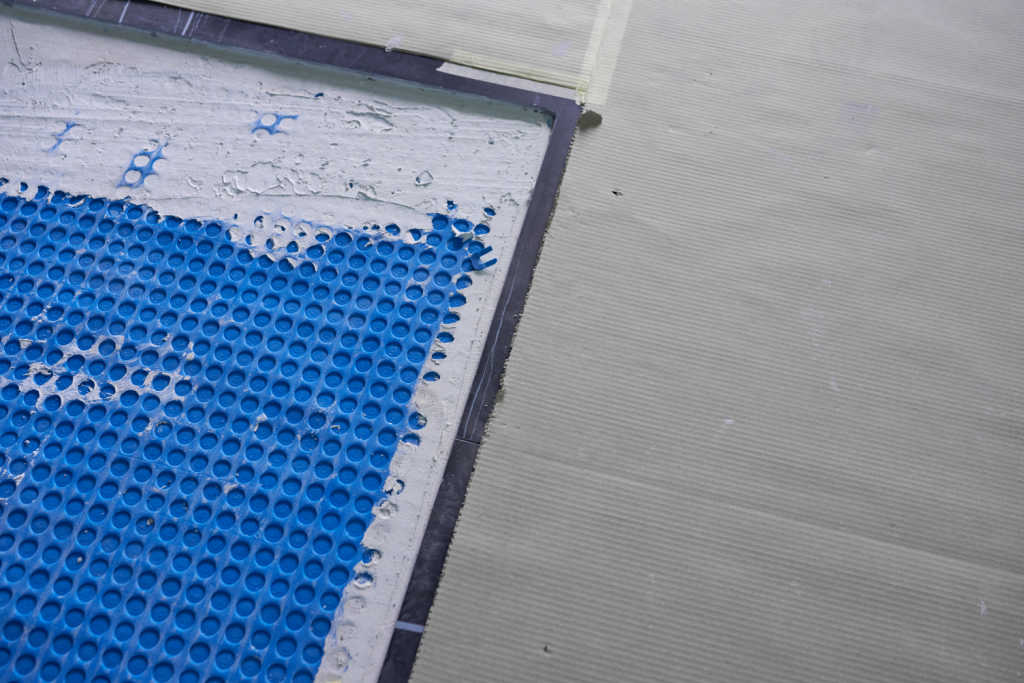

Developing a 3D-printed house requires the use of several processes and technologies. First, you must design a blueprint and send it to a 3D printer for processing. Next, the printer prepares the build platform and loads the raw materials. A robotic arm then moves along rails to lay the build mixture. The most common type of material used for 3D construction is concrete.

Using 3D printing can also help in improving project planning. This technology can be applied at the early stages of the design process. Since it uses CAD plans, 3D models can illustrate different design solutions. This can prove to be a big advantage when it comes to construction. After all, there are many benefits of using this technology, including faster construction and lower costs.

A 3D printer uses additive manufacturing (AM) technology to build a house. It begins by creating a blueprint, which is designed with modeling software. This blueprint can be customized to fit your specifications. Next, you send the design to a 3D printer. The printer uses this blueprint to build the foundation and walls, while human labor is required for other construction and finishing.

Concrete is a common material used for 3D-printed houses. It is cheaper than other frame materials. Because 3D printers can produce small pieces, this method is a great way to speed up the process. This technology also works for custom pieces. It is also possible to design curved walls and foundations using a 3D printer.

Materials used

One of the main raw materials for 3D printing is plastic. The material comes in a variety of colors, textures, and strengths. It’s also the most versatile type of material used in household fixtures and 3D-printed toys. Plastic filament is usually sold in spools and comes in either a matte or shiny texture. These materials are known for their smoothness, firmness, and affordability.

The history of building materials dates back many centuries, and materials have evolved over the ages. Traditional building materials include clay brick, sand brick, and fly ash bricks. But, recent technological advances have led to the development of materials that are less expensive and environmentally friendly. Bamboo, recycled waste, tempered glass, crumb rubber, and Fiber Reinforced Polymer (FRP) are some of the newer options available. With the development of 3D printing technology, this list of building materials has become even more diverse.

Although plastic is the most popular material for 3D printing, metals are also used in construction. Plastics offer many advantages over metals, including their lightweight. This is particularly important in the automotive industry, where the lighter weight of plastics helps cars deliver better fuel efficiency. Another advantage of plastics is the ability to design custom materials that meet the specific needs of a given part.

Concrete is another common material used in 3D printing houses. Concrete is a composite of cement and fibers. This mixture is extruded out of a special nozzle. This process is very fast and solidifies the building material. Concrete 3D printers usually print foundations and walls in layers. The rest of the construction is left to human labor.

No comment